06 Jan SST PURE® ROBOT TESTING IRON RESULTS

Recent independent testing has shown that SST PURE shaft alignment produces significant gains in distance, accuracy and ball speed, it was announced on Monday.

The testing was performed by Golf Laboratories, Inc., at their testing facility in San Diego, Calif. A swing robot was used to test the effects of SST PURE Shaft Alignment on irons. The goal was to isolate shaft orientation as the only difference between two sets of tests shots with the same club head. Three different shaft models were used for testing: a 65 gram graphite shaft – regular flex, a 105 gram steel shaft – stiff flex, and a 120 gram steel shaft – stiff flex. The head for the graphite shaft was a 6 iron with 26.5∞ of loft. The head for the steel shafts was a 6 iron with 27º of loft. The heads were provided by the OEM. The same model of golf ball was used for each shot during the testing, with each ball being new “out of the box”. The same model of grip was installed on each shaft.

The gains in performance with the shaft in the SST PURE position were significant:

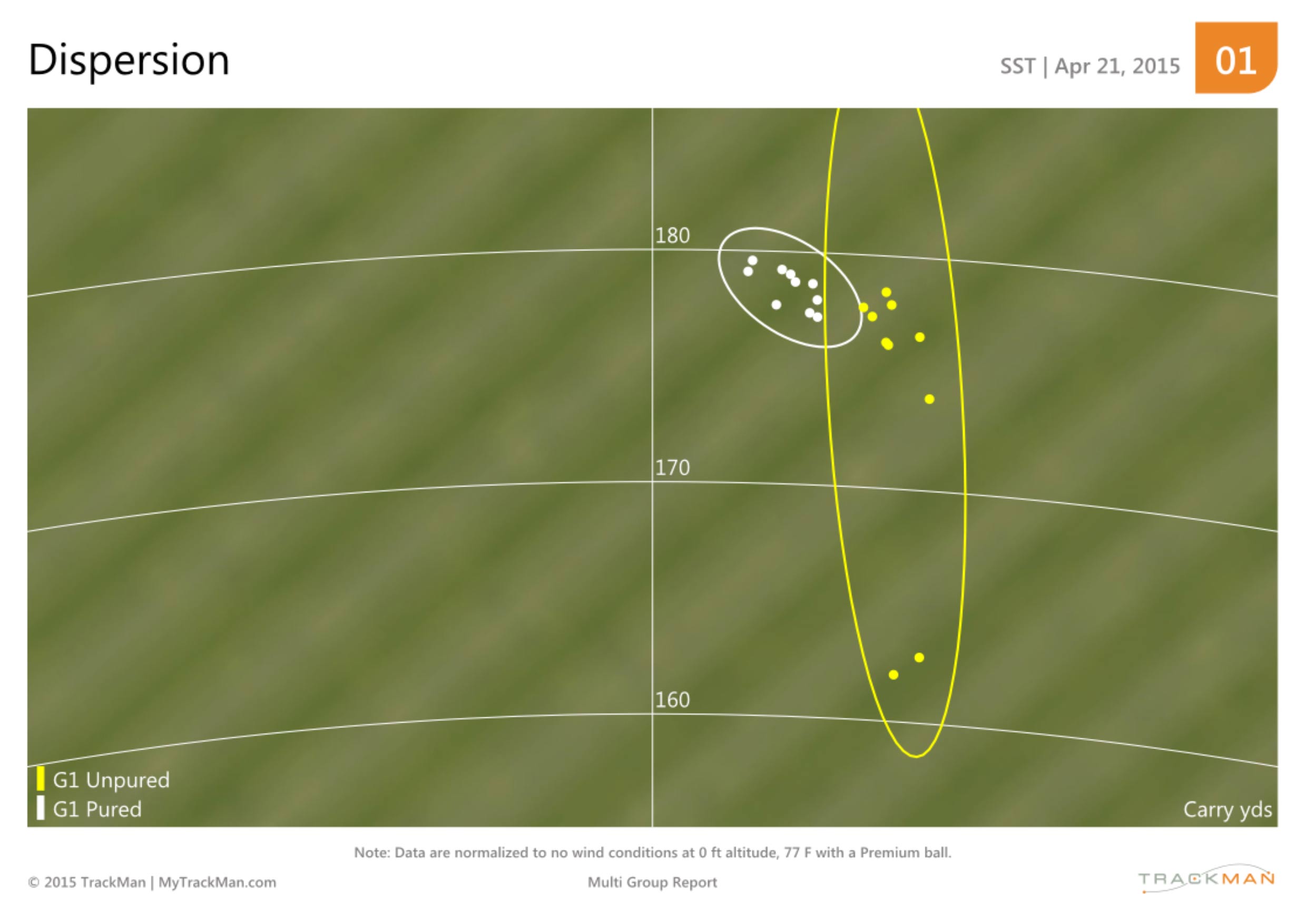

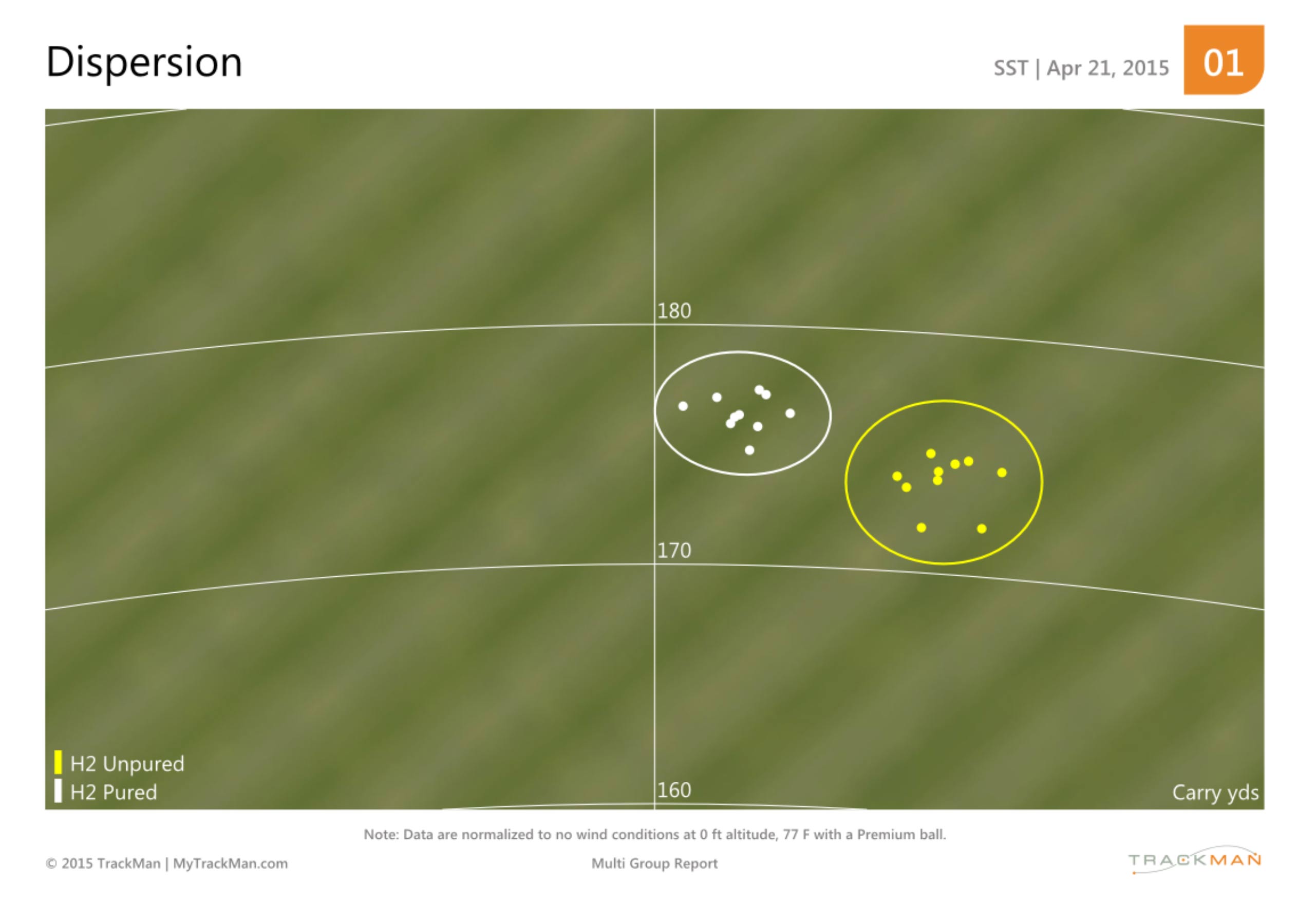

- In terms of accuracy, shots hit by 6 irons with shafts in the optimal SST PURE “neutral axis” orientation finished an average of 13.4 feet away from the center line. On average, PUREd 6 iron shots finished 17.9 feet closer to the center line than shots hit by 6 irons with shafts that were in a suboptimal orientation.

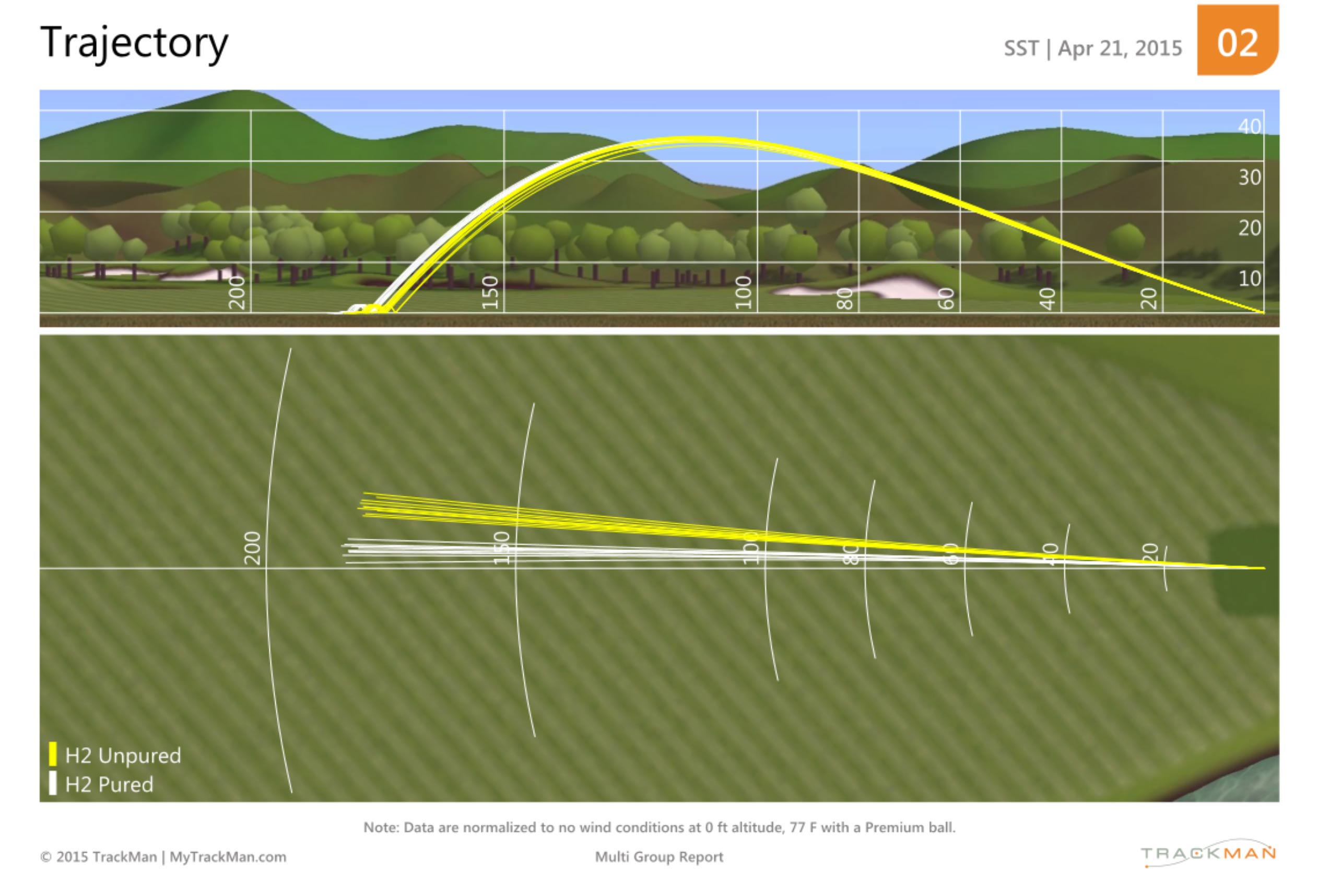

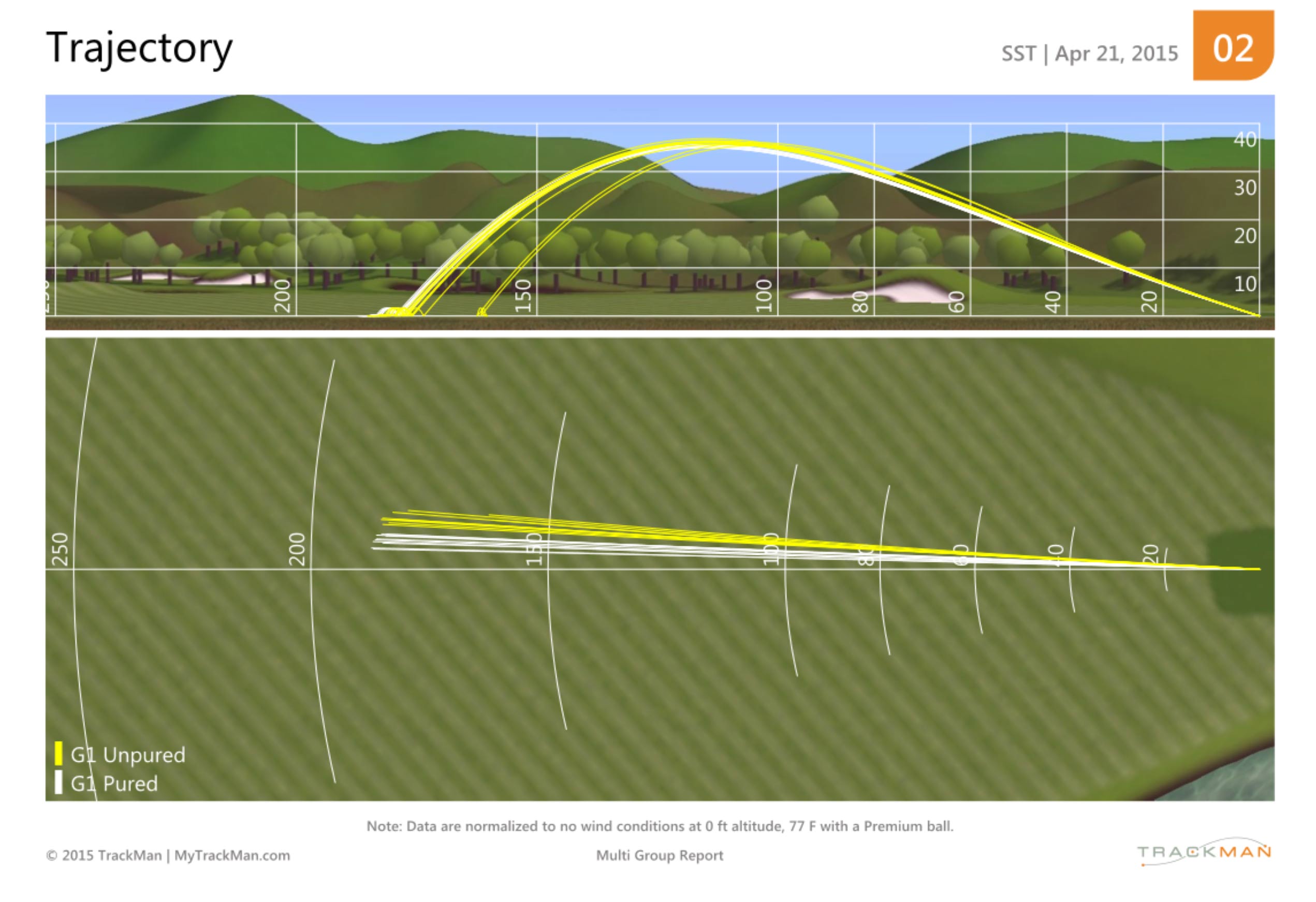

- In terms of distance, shots hit by 6 irons with shafts in the optimal SST PURE “neutral axis” orientation traveled an average of 2.5 yards further in total distance than shots hit by 6 irons with shafts that were in a suboptimal orientation.

- In terms of maximum height, shots hit by 6 irons with shafts in the optimal SST PURE “neutral axis” orientation had an average maximum height of 113.8 feet. On average, PUREd 6 iron shots flew two feet higher than shots hit by 6 irons with shafts that were in a suboptimal orientation.

“Given the repeatability of the robot swing, and all other factors being equal, the difference in performance between the PUREd 6 irons and 6 irons not set in PUREd position is attributed to shaft orientation,” SST President Brian Adair said. “When an iron has its shaft aligned using SST PURE technology it outperforms the same club head, shaft, and grip combination.”

For the golfer, these results will mean that using PUREd iron shafts will lead to hitting shots farther by approximately half a club, hitting shots closer to the hole – 17.9 feet is the difference between a makeable birdie putt and a challenging two-putt, and shots flying higher into the green, which will allow it to land softer and stop.

The test protocol was as follows:

- The shaft was analyzed and aligned using SST’s PURE SPECS automated system to find its most stable, or PURE, orientation.

- Each iron shaft was installed directly in the hosel in the PURE orientation.

- A grip was installed on the shaft.

- The finished club was put in the Golf Laboratories, Inc., swing robot and hit 10 times in the PURE orientation.

- Each shot was measured using a Trackman Golf launch monitor.

- The clubhead was then removed and re-installed into a position deemed by SST staff to be a suboptimal orientation. The grip was not removed when the shaft orientation was changed.

- The club was reassembled in the suboptimal shaft position and hit another 10 times by the robot.

- The 10 shots in each shaft orientation were averaged.

- The process was repeated for each shaft.

SST PURE is a patented process of shaft alignment designed to analyze a golf shaft to find its most stable orientation. Using proprietary computer software and sensitive data-acquisition sensors, the SST PURE Shaft Alignment System quickly locates the “neutral” plane in each shaft. By assembling the club with the shaft in this SST PUREd position, off-line twisting and bending during the golf swing and at impact are greatly minimized. The SST PURE system also generates a printout for each shaft, showing its structural and performance analysis.

The SST PURE process works on any shaft regardless of its material; steel, graphite, even boron or thermoplastic sports equipment benefits from the SST PURE process. All shafts contain irregularities in straightness, roundness and stiffness that are inherent to the manufacturing process. These structural inconsistencies can negatively or positively affect a shaft’s performance depending on how the shaft is aligned.

SST PURE is currently licensed by golf club fitters in 21 states in the U.S. and in 14 other countries including Australia, Bahamas, Canada, England, Germany, Holland, Indonesia, Ireland, Japan, Mexico, Northern Ireland, Scotland, South Korea, and Switzerland.

About SST PURE

SST PURE is a highly sophisticated, patented process through which a golf shaft can be analyzed and its most stable position identified. The top expert club fitters on the PGA Tour and around the world use SST PURE® Shaft Alignment to analyze and align their custom clubs and more and more are becoming licensed. On every major professional tour, the best golfers in the world rely on the groundbreaking SST PURE Shaft Alignment to make sure their golf clubs perform consistently. Players who have SST PUREd their shafts for consistency, accuracy, and distance have won over $2 billion on the PGA Tour.

For more information about the PUREing process, visithttps://sstpure.com.

Follow SST PURE® on Facebook, Twitter, and Instagram to find out which athletes are using the SST PURE process.